HORIZONTAL STORAGE SYSTEMS

Individual horizontal storage concepts for the most diverse requirements

SYSTRAPLAN's individual and tailor-made area gantries have been a well-known name for decades. A few years ago, area storage systems were developed which are able to handle complete stacks with one area gantry. With a combined stack lifting cage, the area storage systems enable both stack and single board transport.This system was adapted for the tire industry to buffer cassette carts in the second level above the production. The full trolleys are stored directly from the extrusion line into the horizontal storage area above and are retrieved "just-in-time" for the next processing step. This saves valuable storage space in production and the internal manual transport between the processing steps.

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

Technical design which makes the difference

Combined single panel and stack transport

The latest generation of area gantries can be equipped with a combined stack lifting cage, which can pick up and separate panels from the stacks up to a length of 3,100 mm. Ideal for strip material as well as kitchen worktops, sides of high cabinets or doors.

The latest generation of area gantries can be equipped with a combined stack lifting cage, which can pick up and separate panels from the stacks up to a length of 3,100 mm. Ideal for strip material as well as kitchen worktops, sides of high cabinets or doors.

The area storage system thus enables both the transport of an entire stack and the safe separation of panel materials from the stack and the transport of individual panels.

The necessary space in the lifting system is created by lifting the clamp frame by means of a separate lift. For the transport of single panels, the clamp system is activated by lowering the separate lift.Safe stack transport, no slipping of the panels

For the storage and retrieval operations the stack lifting frame is put over the stack. Transport fingers swivel under the stack and take up the weight of the stack when lifting it.

For the storage and retrieval operations the stack lifting frame is put over the stack. Transport fingers swivel under the stack and take up the weight of the stack when lifting it.

Under the stacks are either pallets or carriers, which are placed on storage timbers on the floor.

The suction frame of the system is used to clamp the stack by means of its weight during the stack transport in order to avoid possible slipping of the sheet materials.

Suitable for a wide range of materials:

The horizontal storage systems features high versatility in size and stack height, ensuring high flexibility. The flexibility which enables the customer to master the most varied tasks with the most varied requirements. The load carriers will be designed according to the different materials. A large variety of panel materials can be stored and single panels can be picked and feed out, i. e.:

- HPL faced kitchen worktops, KWT (with drip nose)

- High presse laminate ( 0,8 mm HPL )

- Melamine faced derived timber products, 19 mm strips for fronts,

- Solid wood worktops,

- Self faced materials (with overhanging facing material), only stacks with same dimensions

- Veneered board row (with overhanging veneer)

- Row boards (derived timber products i. e. particle and MDF without facing)

- High pressure fibre board (usually 3 mm) one side smooth or faced and the other wire side

- Panels out of plastic materials

- Wrapped boards (with plastic wrapped or with a protection film covered surfaces)

- High gloss faced products

Multiple selection of load carriers:

- Vacuum or magnets

- Needle grippers

- Pneumatically or motor-driven gripping- or clamping systems

- Picking devices for tires or cassette carts for treads

can be adapted according to the requirements of the materials to be stored.

Applications

Horinontal storage system with stack transport for furniture parts for feeding assembly lines

Systraplan has developed an horizontal storage system that is able to handle single panels as well as complete stacks with the same gantry.

Systraplan has developed an horizontal storage system that is able to handle single panels as well as complete stacks with the same gantry.

The system is ideal for small to medium quantities of flat materials that have to be available quickly directly at the machine.

Stacks of panels are stored completely in one single operation. With regard to formats and stack heights, the system is adaptable and therefore flexible in use.

Horizontal storage system with AGV for automatic order picking of desktops

Store a wide variety of doors as a stack and order pick single doors automatically

The most various doors are produced "just in time" today. For this purpose, a line gantry and three horizontal storage systems for the order picking of doors have now been installed at a leading door manufacturer. Years ago, SYSTRAPLAN had already introduced area storage systems that are capable of handling both single panels and complete stacks. The stack transport system is integrated into the gantry. The load support for the individual doors was equipped with specific clamp systems in order to be able to safely separate the most varied door models.

The most various doors are produced "just in time" today. For this purpose, a line gantry and three horizontal storage systems for the order picking of doors have now been installed at a leading door manufacturer. Years ago, SYSTRAPLAN had already introduced area storage systems that are capable of handling both single panels and complete stacks. The stack transport system is integrated into the gantry. The load support for the individual doors was equipped with specific clamp systems in order to be able to safely separate the most varied door models.

Horizontal storage system to store and retrieve cassette carriages for extruded treads in tire production

The SYSTRAPLAN horizontal storage systems with integrated stack transport can also be used for the handling and storage of cassette carts for the tire industry.

The SYSTRAPLAN horizontal storage systems with integrated stack transport can also be used for the handling and storage of cassette carts for the tire industry.

The adjustable gripper is able to automatically pick up different cassette carts and store them on a level above the production.

The fully automatic storage system for the cassettes guarantees low personnel costs. Quick access to the cassette carts avoids waiting times in production and ensures a continuous workflow.

Automatic storage and sorting system for truck tyres

End-produced tyres require adequate storage. For this purpose Systraplan has developed a fully automated solution for sorting, intermediate storage and storage of tyres.

End-produced tyres require adequate storage. For this purpose Systraplan has developed a fully automated solution for sorting, intermediate storage and storage of tyres.

Gripping systems moving on gantries ensure a safe and careful tire handling.

The gripping systems for tyres are also suitable for the individual production processes between tyre production and vulcanisation as well as palletising and picking of tyres in the central warehouse.

Automatic feeding of panel saws

HORATEC in East-Westphalian Hövelhof sees itself as a service provider for the woodworking trade and supplies carpenters and cabinetmakers with customized furniture parts from a batch size of one.

HORATEC in East-Westphalian Hövelhof sees itself as a service provider for the woodworking trade and supplies carpenters and cabinetmakers with customized furniture parts from a batch size of one.

Two panel sizing saws have been combined with a high bay panel storage facility and an automatic gantry feeding system via a master computer and effective software to form a highly efficient and intelligent manufacturing unit. A concept that is proving highly successful.

DANA

Conti

Reasons for a SYSTRAPLAN horizontal storage and retrieval system

Direct feeding of panel saws

The horizontal storage system can also be used for feeding a in the storage system integrated panel saw. In combination with an optional turning device on the suction frame is it possible to turn the panels before feeding. The time while the saw is working will be used for building new consignments or for feeding new material into the storage.High storage capacity

The concept of the horizontal storage systems stands for their high storage capacity. Almost the complete storage area can be used for storing panel stacks up to 2 m height, only with small gaps in between the stacks.

The storage system is able to feed automatically production machines, i. e. panel saws or CNC work centres. It can be used to buffer in between the production steps of simply as pure storage and consignment storage system.Individual design of the storage system determines the performance

Individual requirements are essential for the design of the storage system, therefore a performance can only be given after the layout and concept is ready.

However, it must always be taken into account that in the case of mixed piles, it may be necessary to rearrange the stacks in order to obtain the required material. This influences the performance according to the degree of chaotic storage.No time is lost in the production line

Unmanned operation of the storage system lowers high current labour costs. But even more important is the fast access of the horizontal storage system. Thus no time is lost at the production line. A continuous flow is guaranteed.

The storage processes take place while the buffer built up is processed by the downstream processing systems.

Fast access & automatic operation

Fast access is guaranteed because the system always knows where what has been put away and takes the shortest route for storage and retrieval.

The system works while the next job is already being entered or transferred. During waiting times, the goods can be pre-picked or put away.Storing in a manner which cares for the material and improves the product quality

One of the most important advantages is the damage-free handling of the materials. The area storage systems operate continuously at a comparatively high speed. They can be used to supply production machines, as an intermediate buffer in production or as a pure storage system.Warehouse management and control system

SYSTRAPLANs’ storage and control program can be operated under the Microsoft operating system Windows.

This guarantees that today’s and tomorrow’s requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

Additional interesting information

Foundation requirements for horizontal storage systems

- Load max. 30 N/cm2 alternating,

- Anchorage with expansion anchor or chemical anchor studs,

- Drill hole depth max. 180 mm,

- The load capacity of the floor must be in accordance with the required load,

- Grouting of the foundation plates after installation with shrink free casting compound will be provided by the customer,

- The floor tolerance must be in accordance with DIN18202, sheet 3, line 3 (on the complete length not more than 15 mm)

This information are without any obligations and only reference values. The stated values, especially the exact load capacity, can only be defined after clarification of all details during the design period.

This information are without any obligations and only reference values. The stated values, especially the exact load capacity, can only be defined after clarification of all details during the design period. Details about energy recovery

An increasingly important argument in favour of purchasing a system from Systraplan. Industrial electricity prices have rocketed over the past few years. According to the calculations of the Essen branch of the German Association of Industrial Energy Consumers (VIK), industrial electricity prices have virtually gone through the roof, with an increase of 35%.

Systraplan tackled this subject at a very early stage and has been relying on the proven energy recovery technology for years.

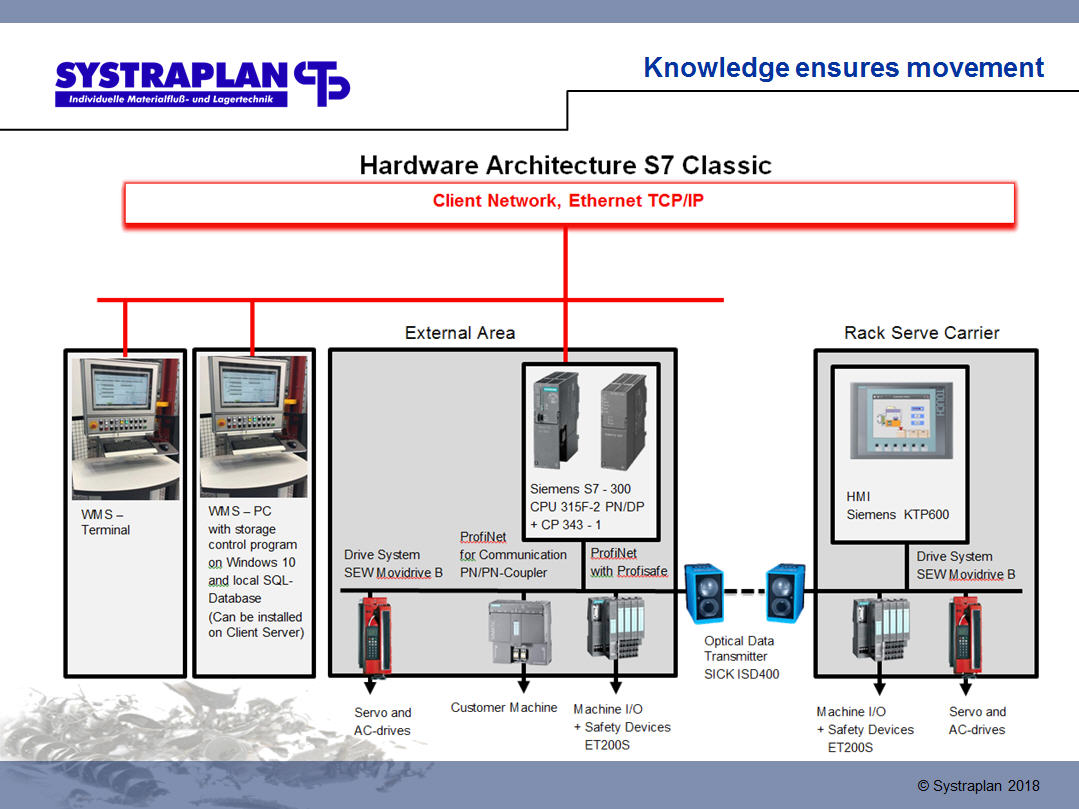

SPS Konzept SIEMENS S7 Classic

Details about warehouse management

SYSTRAPLANs’ storage and control program can be operated under the Microsoft operating system Windows. This guarantees that today’s and tomorrow’s requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

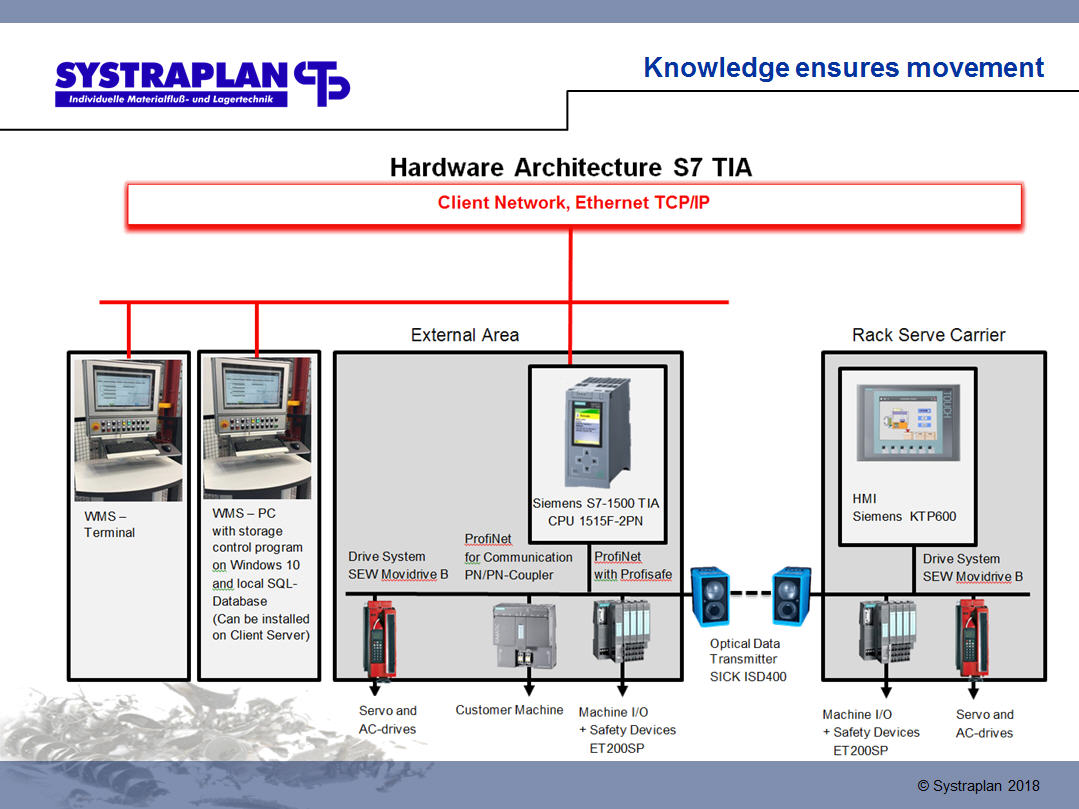

SPS Konzept SIEMENS S7 TIA

Horizontal storage systems

We are developing solutions today for your future needs

Let us know your individual requirements.

We will work out a concept tailored to your needs

We will work out a concept tailored to your needs