Press Release

CLASSEN INDUSTRIES WITH ADDITIONAL HIGH BAY STORAGE IN BARUTH

New Storage System comes from Systraplan

„From an integrated location to an integrated production“, this slogan themes Classen Industries considerable extension of their laminate flooring production in Baruth, Brandenburg. In this way their international competitiveness will be strengthened. The whole concept includes a new high bay storage system from Systraplan for an intermediate storage of raw and decorative boards.The Classen Group produces high quality wood and wood based products for interior applications. In the Laminate flooring market Classen are, with there own words, third largest laminate flooring supplier worldwide. Here the focus in the development of new products is in the DIY sector.

The success of our products is closely connected with it's quality and this is in turn connected to our goal, to keep our customers and products at the forefront of their respective fields.

The success of our products is closely connected with it's quality and this is in turn connected to our goal, to keep our customers and products at the forefront of their respective fields. „Integrated production“

“Integrated production“ incorporates the production of as much as possible components in one plant, managed by Classen Industries. One core component in the production of laminate flooring is the HDF-carrier board.In the meantime Classen has completed the extension of the laminate flooring production in Baruth which was started in autumn 2005.

With the next step the company wants to ensure the supply of the carrier boards with their own MDF/HDF plant. The construction work was started in August 2006, the start-up is planned to go into production in summer 2007.

New high bay storage system from Systraplan

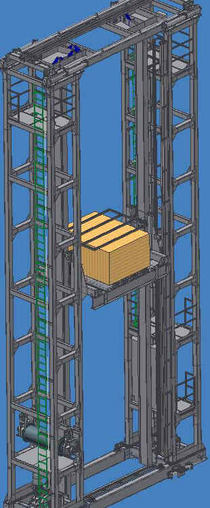

Systraplan, supplier of automatic storage systems as well as board-transport and handling technology, was instructed by Classen Industries to supply for the plant in Baruth a new high bay storage system for an intermediate storage of raw and decorative panels. The steel rack system will be delivered Voest Alpine.

1.700 rack locations for half size board stacks

The high bay storage system has a hight of 20 m and a length of 130 m. Two aisles with a rack serve carrier each and a total storage capacity of 1.700 rack locations for stack of half size panels (2.650 x 2.090).In order to realize the required flexibility and performance each lane has its own area for storing and releasing from stock. Complete stacks of panels will be taken over by the rack serve carrier and stored into one of the rack locations.

Stack heights of 1.200 mm are no problem for the system. Systraplan has already experience in handling stack weights of up to 6.300 kg.

Sliding of the panels is not possible

In order to reach the high speeds and accelerations of the rack serve carrier, the stack with the panels will clamped with a rack which is above the lifting platform. Therefore sliding of the panels is not possible.Direct connection to SAP

The electronic data processing control ensures fastest feeding and discharging, which facilitates the batch-, package- and piece-wise distribution.All goods movement data are adjusted just in time by a direct linking of the full automatic high bay storage system with the merchandise management system. Hence, the sales team can always revert to an up-dated asset of boards provided by an easy and interference-proof operating mode.

Stock-status always available

Systraplans’ storage and control program can be operated under the Microsoft operating system Windows XP. The program code was generated with the 32-bit Delphi development kit. This guarantees that today’s and tomorrows requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

State of the art graphical screen interface

The application has a state of the art graphical screen interface. The user screens are clear, application orientated and easy to use – either by keyboard or by mouse. All information are stored in a standard database.Download of press release

with the text in DOC Format,

pictures in JPG Format und

Layout drwaing in PDF Format

Download of press release

with the text in DOC Format,

pictures in JPG Format und

Layout drwaing in PDF Format

SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

D-32052 Herford

Einsteinstraße 5

D-32052 Herford