Press Release

Increase of Productivity by Storage System from Systraplan

Systraplan, supplier of automatic storage systems, was instructed by Poppensieker & Derix, a company in Westerkappeln, Germany, to build an automatic storage system for construction timbers. At this location an automatic storage for construction timber has been installed. This storage feed on demand the finger jointing plant with material and thus the storage system helps to increase the economic efficiency of the whole factory.

This is the first project of this kind at a laminated timber production. Knowledge and skill gained have given proof that this storage system, which provides the machining elements with material, is extremely reasonable and effective when it comes to the production of laminated timber.

This is the first project of this kind at a laminated timber production. Knowledge and skill gained have given proof that this storage system, which provides the machining elements with material, is extremely reasonable and effective when it comes to the production of laminated timber.Specific Internal Transport

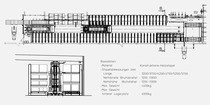

With the storage system stacks up to a length of 5.700 mm and a weight of up to 4.400 kg can be stored.Due to the target-orientated internal transport and demand orientated material feeding of the laminated timber production an extremely high working load of the machining units, operating in multiple shifts, is gained, which results in a very high productivity.

Remains are returned and automatically stored in the storage.

Advantages of Systraplan-Storage system:

- High capacity in spite of less floor space

- Absolute encoder in all measuring systems

- Servo drives require no main brakes (minimisation of mechanical wear)

- Direct access to every single stack

- Carefully transport of the stacks (no damages)

- Saving of energy due to servos with regenerative power supply units

- Flexible system; extension of the rack-system very easily to realise

Storage and Control Program

With the Systraplan storage system comes the 3Tec storage and control program, that can be operated under the Microsoft operating system.This guarantees that today’s and tomorrows requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

Full-Service Fabricator

Poppensieker & Derix is a specialised fabricator for laminated timber constructions.

Poppensieker & Derix is a specialised fabricator for laminated timber constructions.Together with strong partners from the wood industry the group develops and realises national and international projects.

Architects and engineers are supervised. The main focus is on hall structures, also with shapes of a high degree of difficulty.

Core markets are Germany and Europe, if required also even further.

Poppensieker & Derix operates production plants in Niederkrüchten near Düsseldorf and Westerkappeln located near Osnabrück. Further branches are located in Hamburg and Uden (Netherlands).

Quality, Innovation and Customer Service

A combination of experience, that includes eight years of most modern technique as well as precise technical competence, Poppensieker & Derix setting standards on quality, innovation and customer service with the delivery of laminated timber constructions. With the new automatic storage system from Systraplan Poppensieker & Derix is taking the lead in this sector.

With the new automatic storage system from Systraplan Poppensieker & Derix is taking the lead in this sector. Re-investing in the technologic progress and the employment of modern production methods allow to offer quality product at affordable prices.

Download der Pressemitteilung

mit Text im DOC Format,

Bilder im JPG Format und

Layoutzeichnung im PDF Format

Download of press release

with the text in DOC Format,

pictures in JPG Format und

Layout drwaing in PDF Format

SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

D-32052 Herford

Einsteinstraße 5

D-32052 Herford