Full Automatic Picking System

Picking is automatically

The PVA AG in Altendorf, Switzerland, is engaged in trading floors, doors and wooden materials. In mid-March 2011 was, only after two months of installation, a completely new storage system with a customized, fully automated rack serve carriers from the Germans manufacturer SYSTRAPLAN, successfully put into operation. Thus, the over 20 year old, worn-out "storage engine" has been replaced by the newest technology with links to the ERP and to the warehouse management system from CAPS. The aim was to achieve a much higher degree of automation and to store the wood-based panels more efficiently.

Presented at Customer Event

On the occasion of a major customer event on the 26th of March 2011, PVA AG presented to interested visitors the new storage technology with the fully automated rack serve carriers, which are equipped with a suction frame for the gentle picking of single panels as well as telescopic arms for the handling of complete stacks.The paperless order picking with MDE devices, the use of scanners for the electronic collection of material data and and the allocation of the rack locations guaranties a faster and safer process.

"We have set ourselves the goal to achieve with the project, a major logistics optimization and for the benefit of our sophisticated, just-in-time customers." The long-term experience is still missing, but it turns out already now that we are able to store and to pick more rational. And not unimportant for the cost-/benefit-analyses: we have gained additional shelf space with more room for the ever-increasing variety of materials, "said PVA Managing Director and Project Manager Helmuth Schnellmann.

Logistics is a key success factor for a trading company

As first wood-based dealer in Switzerland introduced the innovative PVA AG this groundbreaking new warehouse technology. After the huge project with a unique showroom, which was opened in June 2008, now just over two years later, the implementation of the next major project, to assure further success in the future for the leading trading companies on the Lake Zurich. "Logistics is a key success factor for a trading company with high turnover and short delivery times. Therefore it is important to improve the customer-related processes and optimize continuously.Even the computerized route planning program TOURBOSOFT for fleet planning and delivery scheduling has been used for over four years from us. Also, since we were the first in the industry. So it was only logical to establish a computerized and in the KAPS-integrated inventory management system. So technically, the manifold possibilities of the new high-bay rack serve carriers from SYSTRAPLAN with the 3Tec warehouse management software optimally utilized and applied, "Helmuth Schnellmann about the significance of the project and the logistics for the PVA AG.

New internal procedures and processes caused a corresponding staffing

The profession of a storeman has become a challenging job profile a "logistics", who can deal with the needs of the new technologie can deal with the needs. "An improvement of material goods and security through rational storing reduces the error rate to an absolute minimum. The-right-goods-at-the-right-time-on-the-right-place ', the highest goal of every logistics.On-time deliveries and high product availability is expected

Just today in a boom phase, where time-equals-money, it has an even higher priority to match the customer needs. That is why for our professional customers service quality besides the product and the price is always important. He expects from his suppliers reliable delivery commitments, timely deliveries and high product availability, "says Helmuth Schnellmann, who is responsible for the logistics at PVA.With new technologies, continuous process improvements and good employees wants, the since 1996 as an industry first QMSISO9001 certified PVA AG, to meet the high demands of its customers in the longer term, to be an attractive and indispensable partners with reliable logistics for customers as well as for manufacturers and suppliers.

System description and technical data of the high bay storage system of the PVA AG

At the PVA AG was since exactly 20 years a manually operated storage and retrieval device for picking panels in use. Because of wear and aging of the control PVA AG has considert also the possibility to retrofit the existing equipment.At the end was the price difference between the retrofit and a new system not very large, a new rack serve carrier, however, brings a much higher performance because of the fully automatic operation. Thus, in September 2010, the decision has been made for a new System. The panel storage specialist SYSTRAPLAN from Herford got the order for the delivery of the new system.

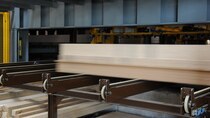

New storage and retrieval devices into existing aisles

The system consists of two high storage bay rack serve carriers that were installed in the existing aisles. Each carrier has a combined lifting platform, one level with telescops for stacks with a weight up to 4,000 kg and a suction frame for picking individual panels. The suction frame is divided into three sections in length, the three parts are controled separately. At that way single sheets for a panels length of 1,500 mm to 5,600 mm can be picked.More storage space as before

Since the required dimensions for each rack location are smaller than for the previous rack system, more storage levels could be installed, making it possible to store more stacks in the warehouse. Since the aisles have basements underneath, special attention was paid to the wheel loads of the rack serve carrier as well as to the installation of the rails, so that vibrations and noises in the basement to be avoided as much as possible.Energy costs by up to 30% off

For the control of the system a Siemens S7 has been used. Integrated energy recovery modules ensures a reduction of up to 30% by feeding the engergy during braking back into the electricity grid. In this way the energy costs are reduced by up to 30%.3TEC warehouse administration software with connection to the existing ERP system

As warehouse administration for the rack serve carrier software from the company 3Tec has been installed. Through an interface to the KAPS material management and warehouse management system of the PVA AG all processes are transparent and quasi-online on the screens.It is also possible to provide order in a special customer frame. These customer orders are directly provided for the tour, which reduce the handling time, because an intermediate manipulation is eliminated.

The supply of the customers could be ensured without interruption during the assembly time

The installation and start up was organzied between the PVA AG and SYSTRAPLAN so that disturbances occur in the operation of the PVA just as much as necessary. Therefore, the installation was planned so that the PVA AG always had one of the two aisles in operation, so that the customers can be served without interruption. Thanks to detailed planning and organization on the part of producer Systraplan and user PVA AG a smooth flow of the entire complex project has been realized.SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

D-32052 Herford

Einsteinstraße 5

D-32052 Herford