Sorting buffer as the final stage

HORATEC und SYSTRAPLAN

a long relationship

- Furniture components for experts -

With this slogan Horatec has established itself for the target group joiners as the market leader in Germany.

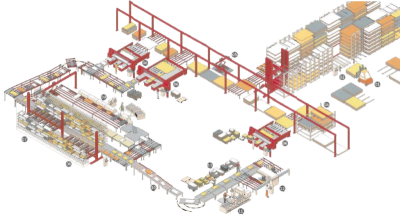

The company, which is located in Hövelhof, Germany since 2002, produces individual furniture from Egger panels, which are distributed to joiners via the timber trade. With the new production line, which has been startet on 04/01/2011, is it possible to cut, edge band and drill up to 3.000 custom-made furniture parts.Behind the state of the art batch size of 1 production line for furniture parts from HOMAG and SYSTRAPLAN stays a a specially designed software solution for the entire process from planning to delivery. Over 3,000 joiner use this planing tool ROOMDESIGNER for the planing of kitchens and individuel furnitures up to to cabinets under the eaves. The resulting data can be used online for the price information as well as for the production at HORATEC. 365 days a year, around the clock is it possible for the customers to send inquiries or orders, which will be calculated automatically within minutes and will be send back as a quotation or order confirmation.

Stage 1: Feed panel saws

The investment of a additional panel saw in 2005 has lead to the decision to automate the handling in order to conect the new saw with the existing saw. Therefor SYSTRAPLAN installed in 2006 a automatic panel feeding gantry for both saws, which has been optimized according to the building requirments. So it was for example possible to realize a passageway for staff and forklifts. The system uses vacuum which ensures careful material handling.The Material is fed by stacks by a forklift via a multi level drawer system. Four preperation places for A-articels are able to provide the material at one access place for feeding the panel saws. The operator has the possibility to provide material for several orders. The saws don’t have to stop while the material fed to the system, because they are separate safety areas.

Cut offs will be handled automatically inside of the systems. In order to save space the system is equipped with a rotating unit, which rotates the cut offs accordingly. The 3TEC warehouse administration software ensures that the cut offs are reused in a optimum way. Scrap can be reduced to a minimum.

Stage 2: High bay storage

In order to get the production more closely to the batch size of 1 and to automate further, Horatec decided in 2006 to install a high bay warehouse system from SYSTRAPLAN.At this high bay warehouse B and C panels are stored and will be feed automatically to the panel saws. The high bay storage is connected via special out feed places with the feeding system of the panel saws. The handling of the panels by vacuum ensures a carefull handling of the material. The building height is used at a minimum floor space usage which ends up at the highes possible storage capacity.

Linking the two systems ensures short lead times and minimum process costs.

Stage 3: Sorting buffer

Since Horatec is a steadily growing company, in 2010 came the decision to expand the production and to automate further. To compensate for various performances between cutting and edge banding, a SYSTRAPLAN sorting buffer has been installed between this two areas. The average performance is 10 parts/min. for in and 10 parts/min. for out feeding. The special of the system is the multi-deep storage, which give the system a capacity of up to 1.900 parts. Storing is done in 2 storing towers with 58 or 51 levels.

The average performance is 10 parts/min. for in and 10 parts/min. for out feeding. The special of the system is the multi-deep storage, which give the system a capacity of up to 1.900 parts. Storing is done in 2 storing towers with 58 or 51 levels.The sorting buffer has to take 2.000 cut parts in 2 shifts. 1.900 parts with an average of 2,5 edges have to be provided to the edge banding machine and over 3 shifts to two drilling machines. Because the parts are labeled and scanned, a secure material tracking is always guaranteed.

The system is integrated in a production planing system from 3TEC. This ensures optimum material and machine utilization, also because of the prodcution of so named “can parts”, which stay in the sorting buffer till they are neede. Already at the planning for sawing optimization a "edge preview will be taken into account.

Since SYSTRAPLAN is a special purpose machine manufacturer, who is able respond flexible to customer requests, was it at each stage possible to find the best concept and thus to the greatest benefit for Horatec.

SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

D-32052 Herford

Einsteinstraße 5

D-32052 Herford