Efficent Volkslager - high bay storage system

Econimic high bay storage system

This concept is interesting for factories who have invested in area storage systems because of reasons of economy. With nearly the same price, the advantages of high bay storage systems are clearly convincing, if compared to area storage.The SYSTRAPLAN rack serve carrier can easily be operated and is nevertheless efficient. If compared to area storage, performance is improved thanks to faster access to the individual types of boards on the rack.

Direct Access in the Warehouse

Restacking usually has to be done in area storages with piles up to 2 metres in order to access the boards, requiring much time and energy. This job can be dispensed with now.With low piles in the rack system the rack serve carrier directly withdraws the board material. In this way a large variety of different types of boards can be taken from the rack without having to restack them.

To remove them from stock, the individual boards are fed safely and directly to the panel saw by a vacuum system which is extended via telescopes to both sides.

Direct Connection to a Panel Saw

With this type of storage system, it is part of standard technology today to directly link the system to panel saws.Panel saws of many different manufacturers have been employed in a large number of projects.

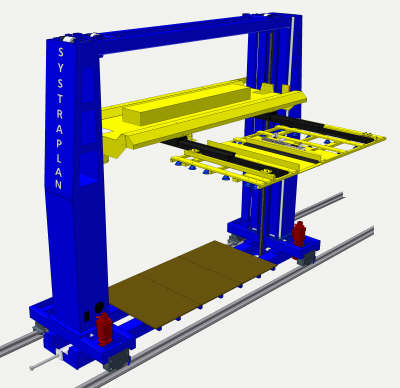

Newly Developed Rack Serve Carrier

To customers and competitors, SYSTRAPLAN stands for solidity, reliability and commitment.The key element of the new concept is a rack serve carrier newly developed for the lower price segment. You will see at first glance that it is entirely different from the known conventional rack serve carriers, at least from aspects of design.

Gentle Handling

One of the major benefits is the handling of the wood material without causing any damage to it. Within a short period of time, the delicate boards are prepared for processing in an appropriate way.Commissioning Right on the Rack Serve Carrier

The individual boards are commissioned right on the rack serve carrier. For this purpose, a platform was included into the basic frame. Therefore, no particular area is required for commissioning.Utilizing Warehouse Height

Even if the store is only 4 metres high, the high bay storage system is able to compete with area storage. Assuming homogenous floor utilization of 200 m2, i.e. approx. 30 meters length and close to 7 metres width, this roughly means up to 80 stock sites.

A corresponding area store will feature up to approx. 25 stock sites. Benefits from high bay storage increase as the stock gets higher, enabling the manufacturer to handle the grown variety of products.

Direct Storing of Piles

In order to store entire piles, a fork lift truck can place them on the floor level of the rack system from the outside. The rack server carrier accesses these piles from inside by means of its vacuum system.With several stock sites, distributed over the exterior of the rack, the user can thus store the piled boards quickly and directly.

Warehouse Lay-out Customized to Customer Needs

While offering a large variety of options, the system is expandable and can be adapted to the individual customer’s situation in terms of performance and space.On demand the rack serve carrier can even handle the entire pile.

Warehouse Management by Siemens S7

The warehouse is managed by a specially developed software based on SPS, and is operated from the operating panel.

PLC warehouse administration system >>>

Moreover, the customer can choose a PC-controlled warehouse management system, enabling him to establish a connection to superior control units.

Warehous Administration System on PC Basis >>>

Download of the press release

with text in DOC format,

picutres in JPG format

Basic data check list:

PDF DownloadVideo:

Volkslager Simulation

SYSTRAPLAN GmbH & Co. KG

Einsteinstraße 5

D-32052 Herford

Einsteinstraße 5

D-32052 Herford