Warehous Administration System on PC Basis

Description of Storage and Control System

SYSTRAPLANs’ storage and control program can be operated under the Microsoft operating system Windows. This guarantees that today’s and tomorrows requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software. The application has a state of the art graphical screen interface. The user screens are clear, application orientated and easy to use – either by keyboard or by mouse.

The application has a state of the art graphical screen interface. The user screens are clear, application orientated and easy to use – either by keyboard or by mouse.All information are stored in a standard database.

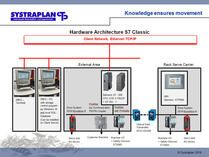

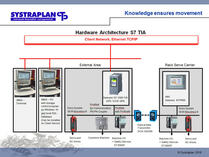

The personal computer is linked by a special interface with the PLC control system (e.g. Siemens S7, Allen Bradley). All tasks and handling orders will be executed by this system.

Data exchange with a higher ranking production planning and control system is possible via a local area network (LAN). The data transfer can be done e.g. by standard ASCII files. Normally, data about the handling jobs and status information about the equipment are transmitted. Such data could be stored, updated and retrieved on a central computer.

The software code is modular and will be adapted for each project to the specific mechanical design of the rack serve carrier and the organization structure of the client.

The software for the storage control consists of following standard features:

1. Administration of material data

A virtually unlimited number of different materials can be stored (only limited by hard disk capacity):

- Unique material no. with unlimited number of digits

- Name of material / code

- Dimensions (length, width, height)

- type of storage (see below)

- Group no. (only by rainbow or dynamic storage)

- Minimum stock requirements

- Additional information as e.g. supplier, costs, etc.

Following kind of storage system are common:

Fixed allocation storage

Each storage place has a fixed pre-allocation about specific material to be stored. Each material handled will be only stored in places which are pre-allocated.This kind of storage is mainly used for material which is handled very often and in large quantities.

Rainbow storage

This type of storage means that different type of material pieces are stored in the same storage place, but stacked.This type of storage requires in most cases a restacking of material to reach that piece which should be taken off.In order to apply rainbow storage with necessary restacking there should be at least two empty storage places available.The storage control program assures automatically that all the time such necessary restacking places are available. Therefore it is always possible to retrieve the lowest part of a stack by restacking the parts above.

This type of storage is used

- for material rarely used

- for storage system with small lots of same material

Idle production time caused by restacking of material can be compensated by pre-commissioning. Please refer also to chapter 4.2 (discharging of material)

Dynamic storage

In case of dynamic storage each storage place contains only the same material (similar as fixed allocation) However, each storage place is not allocated to a specific material but to a material group. Such a material group can consist of several kind of material with different characteristics.The first material placed in such a storage place determines the material for this specific storage place. After complete clearance of the storage place, the system is able to store then a different material, belonging to the same material group, in this storage place.

Dynamic storage is mainly used for material often needed which is handled in different quantities, when there is not enough storage capacity to allocate fixed places.

The list of material (material accounts and present stock) can be printed. The printer is usually integrated in customers LAN and is not part of the standard scope of supply.

The print menu offers e.g. following selections:

- Print all material data included in material accounts

- Print material data only which are stored at time of print in the storage system

- Print material data only when the stock falls under a preset minimum value. This enables the client to reorder material.

2. Administration of storage places

For each storage place following data set are available:

- Unique number of storage place

- Type of storage (fixed / rainbow / dynamic)

- Kind of material to be stored (if material is fixed allocated to storage place)

- Group no. (for rainbow and dynamic storage)

- maximum permissible stack height

- Status whether place is occupied or not

- Information about special places e.g. place to build up commissions or place for base boards, etc.

3. Administration of storage place content

The program keeps track of each content at a specific storage place with following data:

- Date of input

- Stack height / number of stack pieces

- Number of stacks in depths view

Any handling of material (feeding / discharging / rearranging) automatically updates these data accordingly. However, manual corrections are also possible.

It is possible to display on the screen all places of storage of one specific material.

4. Storage operations

Following types of handling are integrated in the system:

- Feed of material from an feed place(s)

- Discharge of material to production lines

- Discharge of material to discharging place(s)

- Rearranging of material within the store

4.1 Feeding of Material

Type of material and number of pieces to be stored in will be entered at the storage control computer or a separate input terminal by an operator.The program determines automatically the correct storage places and instructs the PLC with the corresponding jobs.

After job execution, the material will be booked in the program for the place entered.

4.2 Discharging of material

The data of boards to be discharged are stored in tables with material number and number of pieces. Such tables can be generated either manually or can be provided from a production planning system.The storage control program determines automatically the source place for the next requested material. In case there is more than one possible source place, the system applies further criteria for selection as stack height, first in- first out, etc.

The program instructs the PLC with the corresponding jobs. The PLC executes the handling from the source place to the discharging place or to the production line.

In case of rainbow storage the storage program has an additional operational mode – the pre-commissioning. This program mode reduces idle time caused by rearranging of boards and speeds up feeding of production lines. In this mode the rack serve carrier forms one or two commissions on special places during break times or during night time.

4.3 Rearranging of material

There are some reasons which might require to rearrange material within the store:- to collect same material in one place which is spread over multiple storage places

- to restore material which accidentally was stored under wrong material number

Such rearrangement jobs are entered manually by typing in source place, destination place and number of pieces. Such jobs will be executed in sequence manner.

5. Link to LAN Network

The storage control computer is integrated in a local area network (LAN). The centralized data pool of the server computer is available via this link. Furthermore jobs are transferred from the server to the storage control program and data backup can be executed.

The hard- and software for the LAN connection is customer specific and usually provided by the customer. The progress of any charging or discharging operation can be saved on the server. Therefore, the status of the daily production and also single jobs can be surveyed from an office computer. The production is more transparent and possible interruption can be discovered and solved earlier.

The storage control program runs also a log file consisting of all jobs which are to be executed, either successfully or faulty. Such a log file can be also transferred to the server and can be evaluated in all thinkable respects.

6. Administration of Remains (optional)

The storage control program can also handle reusable remains from board cross cutting. The system prints labels for tracing of material. The remains are recharged into the store.

Charging and discharging of remains can be manually carried out, semi automatic and fully automatic.

7. Office Version

In addition to the storage control program, SYSTRAPLAN provides a special program for office use which enables users to control the stock and the progress of the order execution. Most information can be printed for filing.

8. Link to customers production system

The data transmission from the storage control program to the customer production system is carried out by an ASCII-file. The data structure can be defined individually during design phase.

Download of a detailed description.