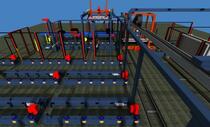

GREEN TIRE LOADING SYSTEM

Gentle handling for green tires

Green Tyre loading and unloading systems are used for the careful handling and the continuous flow of spraying lines.

In the tire building area a green tire transport system is existing in order to collect the green tires from the TBM’s and handle the material flow through a spraying process.

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

Advantages

Relief from heavy workloads of physical activity

In particular, the dimensions and the weight of truck treads are in a range where the manual handling is linked with a heavy burden on the human body. This inevitably leads to the fact that the employees do not handle the strips gently in order to cope with the workload.Higher cycle rates

Increasing cycle outputs on the tire building machines also force the tire manufacturers to think about an automatization of the green tire loading process.

Uninterrupted feeding of the green tire leaf trucks

Standstill of the tire building machine is avoided by the automatic and uninterrupted loading of green tires, thus increasing the productivity of the tire building machine.Increase in quality by means of an automated green tire handling

The manual feeding inevitably results in an improper handling of the green tires in order to cover the workload and, as a consequence, deformations of the green tires occur at the expense of the quality of the finished product.

Green tire loading

We are developing solutions today for your future needs

Let us know your individual requirements.

We will work out a concept tailored to your needs

We will work out a concept tailored to your needs

Technical design

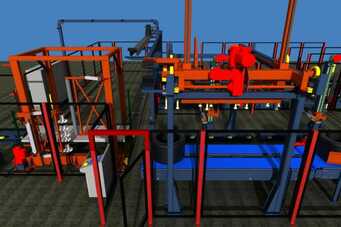

Accumulation and positioning of the green tires

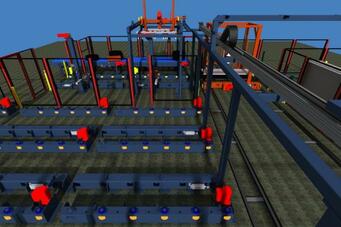

The tires arrive on customer’s roller conveyors and are transferred onto an belt conveyor with spring loaded flaps for centring. Behind the belt conveyor, two parallel belt strands with incorporated rollers and 4 stops in between the belts are installed in order to position a lot of 3 or 4 tires.

The tires arrive on customer’s roller conveyors and are transferred onto an belt conveyor with spring loaded flaps for centring. Behind the belt conveyor, two parallel belt strands with incorporated rollers and 4 stops in between the belts are installed in order to position a lot of 3 or 4 tires.

The stops are pneumatically activated and stop the tires from the inside. There are two fixed stop positions for stopping 3 or 4 tires. For positioning 3 tires each of the stops can be moved pneumatically.Gentle green tire picking and loading

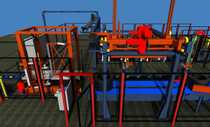

After positioning the 3 or 4 tires on the conveyor (take-off position), the lifting device of the handling unit moves the fingers of the picking devices in the centre of the tires. The picking of the green tires would be done with the fingers from the inside, with a planetary gear to open and close fingers via a pneumatic motor.

After positioning the 3 or 4 tires on the conveyor (take-off position), the lifting device of the handling unit moves the fingers of the picking devices in the centre of the tires. The picking of the green tires would be done with the fingers from the inside, with a planetary gear to open and close fingers via a pneumatic motor.

The pressure of the fingers is adjustable. The pneumatic motor ensures a gentle handling from the inside without damaging the inside of the green tire. During the picking process the tire automatically get centred by the fingers of the picking device.

After picking the tires with the fingers, the lifting device takes the lot of 3 or 4 green tires up and moves them on one of the leafs of the truck, which is waiting in loading position.

The system automatically adapts to the different types or green tires specified, without any set up required and no waiting time. The information on type and size of the green tires to be loaded is made available by the PLC of the green tire transport system.

The system automatically adapts to the different types or green tires specified, without any set up required and no waiting time. The information on type and size of the green tires to be loaded is made available by the PLC of the green tire transport system.

The next leaf is subsequently folded down by a pneumatic cylinder in horizontal position.

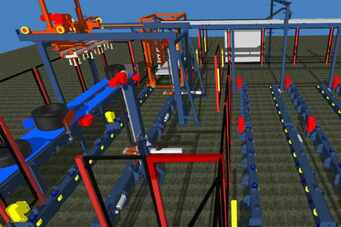

Depending on the lot size, 3 or 4 tires per level of the green tire truck can be loaded. In case only 3 green tires are to be loaded per side, one picking device will be moved out of the system and the remaining 3 picking devices are pneumatically positioned on linear sets according to the 3 tire lot dimensions. The stoppers on the in feed belt conveyor are going to stop the tire accordingly.

Depending on the lot size, 3 or 4 tires per level of the green tire truck can be loaded. In case only 3 green tires are to be loaded per side, one picking device will be moved out of the system and the remaining 3 picking devices are pneumatically positioned on linear sets according to the 3 tire lot dimensions. The stoppers on the in feed belt conveyor are going to stop the tire accordingly.

The system will adapt automatically to the different configurations without any impact on the required cycle time. The basic version consists of 4 picking devices and 4 stoppers that are to be positioned within the pickup station.

Automatic truck change

As soon as all leaves have been loaded in this manner, the filled truck is automatically transferred by the truck transport system right to the empty despatch position. Simultaneously, an empty leaf truck standing in waiting position on the cross cart is automatically being moved into the loading position. Also, new tires have been simultaneously accumulated to a new charge so that a new loading cycle can start.Green tire truck buffer

The empty trucks are inserted manually by an operator into one of the in feed slots. Each loading system has two loading slots. The assignment of the truck type to the empty buffer slot is fixed according to the above configuration table.

Depending on the arrival sequence of the green tires lots on the outlet (order list), the system automatically selects the correct truck type. A cross cart is taking the right cart and pushes it to the loading position. Information about the current production of the existing TBM’s will be made available by the PLC of the green tire transport system.

Depending on the arrival sequence of the green tires lots on the outlet (order list), the system automatically selects the correct truck type. A cross cart is taking the right cart and pushes it to the loading position. Information about the current production of the existing TBM’s will be made available by the PLC of the green tire transport system.

During travelling on the cross cart the leaves will opened automatically. In order to ensure that the leaves are open is at the loading position a sensor detecting the open leaves.