HIGH BAY RACK SERVE CARRIER

Increase in quality and a wider range of varieties through fully automated high bay storage and retrieval systems

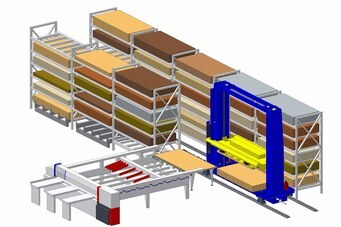

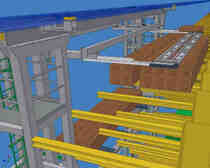

SYSTRAPLAN's individual and tailor-made systems are well known, especially in the wood and panel industry.Through the intelligent combination of lifting platform (access to a single panel) and stacking platform (transport of entire stacks), the storage and retrieval machines offer optimal characteristics for effective and space-saving storage.

Systraplan, specialist for storage technology of panel material, can look back on a long tradition in the development of possible machines in the panel industry.

The experience SYSTRAPLAN has gained over the years with the production of this equipment has been incorporated.

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

Technical design which makes the difference

Direct order picking on the rack serve carrier

With this high bay storage system, which was developed by Systraplan , stacks as well as single boards are moved. Among the transport of stacks and single boards the commissioning is directly proceeded in the high bay storage system.

Therefore, an additional area for commissioning is not necessary. Remaining quantities simply stay in stock. This saves time, space, energy and extra appropriation for commissioning.Damage-free handling

One of the most important advantages is the damage-free handling of the derived products. Within short time the sensitive boards are appropriately prepared for the resale. By doing so the automatic high bay storage system operates continuously at a comparatively high speed. It just takes a quarter of an hour to build a consignment of 15 different boards.Direct connection to production

A direct connection of this storage technology to producing machines, i. e. saws, are already standard and proved to be very advantageous.

Handling of a wide range of different loads and dimensions

Whole stacks are taken over and are assigned to a storing place by the high bay storage system. Later the telescopic-suction arms remove single boards from the stack for order commissioning. The load suspension means are prepared and constructed for boards with most different dimensions.

The dimensions vary from 2,800 mm to 5,800 mm in length and 400 mm to 2,500 in width. The high bay storage systems must be able to store stripe materials multiply deep in order to achieve a most possible high filling ratio or complete occupancy. The maximum stack weight can achieve up to 5 tons.Separate working lifting platforms

SYSTRAPLAN has developed a rack serve carrier which obtains a considerably higher performance with two independent working lifting platforms. In comparison to conventional rack serve carriers this system works with two lifting platforms which can be controlled independently. Each platform is equipped with own lifting drives and load suspension devices, which can work to both sides of the aisle. Due to the independent working from each other a 20 % higher output in comparison to conventional systems can be achieved.

Applications

Full and half format panels for the furniture industry

Full and half format boards (5610 x 2070 mm or 2805 x 2070 mm) for the furniture industry are automatically stored and retrieved, both as complete stacks and as single panels, with the storage and retrieval machine. The handling of both dimensions in one storage system is possible.

Full and half format boards (5610 x 2070 mm or 2805 x 2070 mm) for the furniture industry are automatically stored and retrieved, both as complete stacks and as single panels, with the storage and retrieval machine. The handling of both dimensions in one storage system is possible.

Picking of the single panels is done directly by the rack serve carrier. With a flat suction frame the panels can be separated safely directly from the stack in the rack. Either an consignment stack is formed in the storage and retrieval unit on the stacker telescopes of the stack lifting platform or a panel saw is fed directly.

High-bay storage with direct connection to the dividing saw

A direct connection of the high-bay storage to panel saws is standard and has proven to be very useful at this point.

A direct connection of the high-bay storage to panel saws is standard and has proven to be very useful at this point.

The panels or panel stacks are usually fed to the saw from the rear via an extended saw table. Panel saws from various manufacturers have already been integrated in numerous projects.

Kitchen worktops / Strip storage with multiple deep storing

The strips (in lengths from 2800 mm to 5,600 mm and in widths of 600 mm, 900 mm and 1,200 mm) are stored multi-deep in a cantilever rack. The automatic access to single sheets is done despite multiple deep storage.

The strips (in lengths from 2800 mm to 5,600 mm and in widths of 600 mm, 900 mm and 1,200 mm) are stored multi-deep in a cantilever rack. The automatic access to single sheets is done despite multiple deep storage.

The picking devices are prepared and constructed for a wide range of panel dimensions. The structure of the racking system allows a flexible use of the rack, so that any size of board can be stored in all rack locations.

Strip material for longitudinal storage in honeycomb racks

The stacks are stored on base boards lengthwise up to 4400 mm in depth in a honeycomb rack. The base boards have a standard width according to the shelf compartment width, the stack of strips on the base board can be narrower.

The stacks are stored on base boards lengthwise up to 4400 mm in depth in a honeycomb rack. The base boards have a standard width according to the shelf compartment width, the stack of strips on the base board can be narrower.

Different shelf widths and depths can be combined. With this solution, too, both complete stacks and individual boards are stored and retrieved fully automatically.

Storage as heart of a modern production for timber building

The various carrier platforms can be loaded with a maximum payload of 6 tons in a variety of ways. There is space for raw boards, for example made of gypsum plasterboard or wood composite material, as well as already processed beams or cuttings. This allows a colorful and varied use of the rack system. The carrier platforms of the system can be loaded directly from the outside via two inbound stations.

The various carrier platforms can be loaded with a maximum payload of 6 tons in a variety of ways. There is space for raw boards, for example made of gypsum plasterboard or wood composite material, as well as already processed beams or cuttings. This allows a colorful and varied use of the rack system. The carrier platforms of the system can be loaded directly from the outside via two inbound stations.

Most different materials for the timber trade industry

It takes many years of experience to do automated picking of the most different materials and surfaces, as they are common in the timber trade, safely and material-friendly.

It takes many years of experience to do automated picking of the most different materials and surfaces, as they are common in the timber trade, safely and material-friendly.

The systems, especially for the separation of the panel materials, are specially designed to meet the needs of the customer. Over many years SYSTRAPLAN has equipped numerous timber dealers with automatic storage and order picking systems.

Melamine paper pallet storage with connection to short cycle press

Our automatic high-bay warehouse for the storage of melamine paper pallets, with a variety of different decors, ensures the "just-in-time" supply of melamine papers at the KT lines, thus ensuring continuous production at the short-cycle presses.

Our automatic high-bay warehouse for the storage of melamine paper pallets, with a variety of different decors, ensures the "just-in-time" supply of melamine papers at the KT lines, thus ensuring continuous production at the short-cycle presses.

When preparing the pallets for the short-cycle press lines, the system always accesses the stack of the same grade that was started last.

With the help of a direct connection to the short-cycle press, a very fast decor change is ensured. Remaining pallets can go directly back into the high-bay warehouse.

High bay storage and order-picking for HPL sheets

HPL laminates are used in various areas. This applies to kitchen worktops, construction elements and equipment in wet and humid rooms, etc. All products that are increasingly being manufactured to customers specifications and commissions.

HPL laminates are used in various areas. This applies to kitchen worktops, construction elements and equipment in wet and humid rooms, etc. All products that are increasingly being manufactured to customers specifications and commissions.

With the Systraplan storage system these HPL sheets can be separated from the stack automatically and gently to form a consignment stack in the rack serve carrier. Due to the high material value of the HPL sheets a particularly gentle handling is important. Damage, which cannot be excluded with manual handling, can be avoided by a fully automatic handling.

Storage and sorting system for natural stone or granite slabs

With the automatic SYSTRAPLAN storage system, both raw slaps and already processed panels can be flexibly stored and retrieved. The processed panels are stored between the processing steps and are retrieved for further processing - in a newly grouped arrangement.

With the automatic SYSTRAPLAN storage system, both raw slaps and already processed panels can be flexibly stored and retrieved. The processed panels are stored between the processing steps and are retrieved for further processing - in a newly grouped arrangement.

The targeted, internal transport and the regrouping according to the subsequent work steps result in an extremely high utilization of the processing machines, which leads to a considerable productivity.

Commissioning of plasterboards of different lengths

Individual panels are taken from the storage locations by the rack serve carrier and order picked directly as a consignment on the rack serve carrier. The system creates the stack lengthwise, starting with 6 m long panels and then stacking successively shorter panels up to 2.4 m in length.

Individual panels are taken from the storage locations by the rack serve carrier and order picked directly as a consignment on the rack serve carrier. The system creates the stack lengthwise, starting with 6 m long panels and then stacking successively shorter panels up to 2.4 m in length.

One side serves as a reference line for alignment. The formed stacks are temporarily stored on a conveyor until they are removed by a forklift truck. At the same time, a batch card is printed, which is fed to the respective stack for identification.

THE VOLKSLAGER

Our concept for a economic high bay storage system

This concept is interesting for factories who have invested in area storage systems because of reasons of economy. With nearly the same price, the advantages of high bay storage systems are clearly convincing, if compared to area storage.In the meantime, many customers have decided for the storage system. The new SYSTRAPLAN rack serve carrier can easily be operated and is nevertheless efficient. If compared to area storage, performance is improved thanks to faster access to the individual types of boards on the rack.

Reasons for a SYSTRAPLAN high-bay storage system

Automated warehousing

- Men less operation of the Systraplan system. Nightshifts also possible.

- Full automatic in and outfeed of stacks and single boards. Rainbow stacks can be built or destacked.

- Year to year savings of labor and costs for the fork lift trucks.

- The storage and conveyor system does cause no damages to the transported goods compared with forklifts.

- The storage system can work independent, in case of a 2 level buffing stations for infeed and outfeed. No waiting time for the storage system and for the connected production machines.

Speed of the system

- Fast system because no time is wasted. The system always uses the optimal path.

- Fast system, because the RFZ has access to every single pile without having to move numerous other piles first.

- To minimize cycle times, the driving and lifting movements are carried out simultaneously.

- Fast system because the RFZ can work to both sides of the aisle without having to move to the end of the aisle to swing the fork to the other side, as with a narrow aisle stacker.

- The retrieval according to the FIFO principle (first in - first out) can be realized in an optimal way - if it is desired.

Optimal use of space

- Use of the hall height, high storage density and instant availability.

- Optimal use of the space because of the better height with the racks and because of the very tight and exact placed goods.

- Self supporting rack structure avoiding forces to existing workshop roofs and walls.

- Rack design is based on standard hot-rolled steel profiles.

Many years of expertise

Experienced system which has been built several times and which is working without problems at many places. Complete system including the warehouse administration out of one experienced Hand.

- 10 years and more with min. maintenance costs. Little wear because of the driving on rails.

- Very low energy consumption because of installed energy-back-feeding-modules

- A menu-guided control system is used to control and manage the rack storage system making it safe and easy for the operator to run the storage processes.

- Permanent stock control by the warehouse administration. Access true the network from the office without additional license. Flexible warehouse management software in combination with a PLC control system.

- The system is equipped with a modem to serve the program from Germany in case of problems.

Additional interesting information

Fire protection & sprinkler system

The fire protection equipment must be designed in accordance with local regulations and coordinated with the local authorities. The regulations vary greatly from site to site, so that there is no typical fire protection.

In some cases insurance companies prescribe a certain level of fire protection, otherwise the rates will increase dramatically. This must be agreed individually with your insurance company.

If a sprinkler system is required on the shelf, it must be decided how many shelf levels must be sprinkled with how many sprinkler heads. Then the piping and the position of the sprinkler heads must be determined. The pipes and the heads must be in the shadow of the shelf frames, otherwise additional space and in the shelf compartment would be required.Installation site / earthquake zone:

Please check and inform us about the earthquake zone to be considered. The earthquake zone is important for the design of the shelf structure, which has a significant influence on the price. The customer is obliged to inform Systraplan about the earthquake zone as well as the ground class of the later installation site. If we do not receive any information, no earthquake zone will be taken as a basis for the price calculation.

Details about energy recovery

An increasingly important argument in favour of purchasing a system from Systraplan. Industrial electricity prices have rocketed over the past few years. According to the calculations of the Essen branch of the German Association of Industrial Energy Consumers (VIK), industrial electricity prices have virtually gone through the roof, with an increase of 35%. Systraplan tackled this subject at a very early stage and has been relying on the proven energy recovery technology for years.

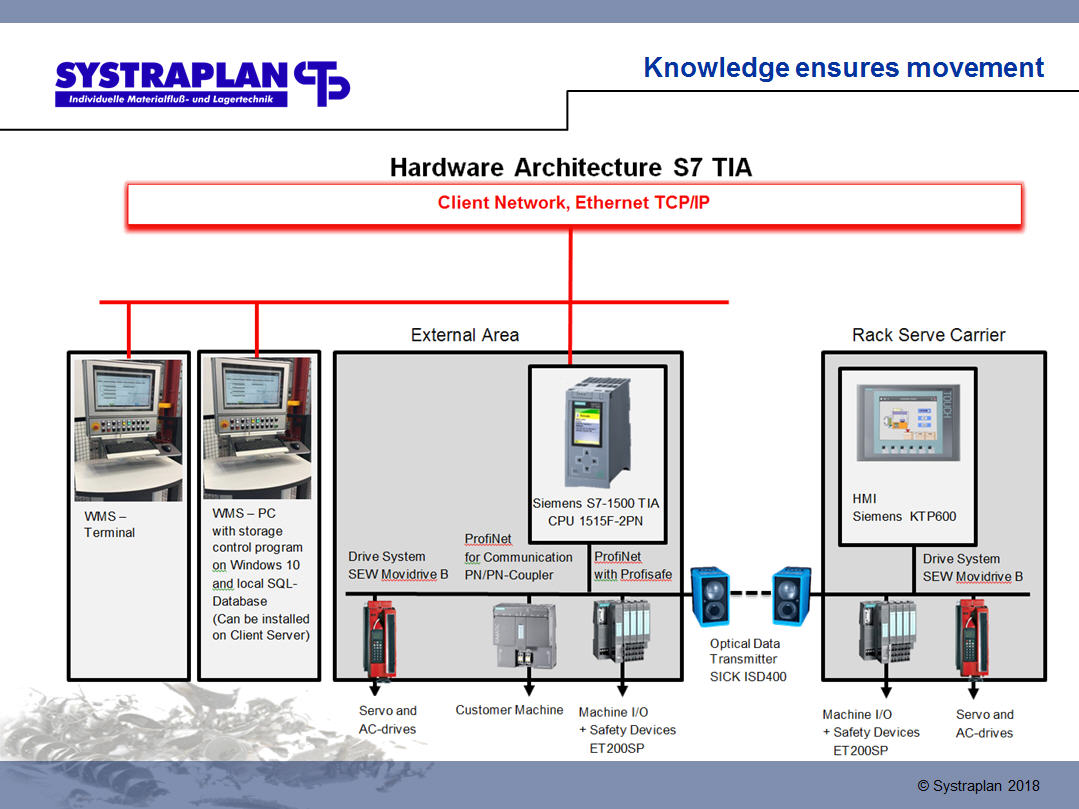

Details about warehouse management

SYSTRAPLANs’ storage and control program can be operated under the Microsoft operating system Windows. This guarantees that today’s and tomorrows requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

SPS Concept SIEMENS TIA

High bay storage systems

We are developing solutions today for your future needs

Let us know your individual requirements.

We will work out a concept tailored to your needs

We will work out a concept tailored to your needs