The Volkslager

Our concept for a cost-effective high-bay storage system

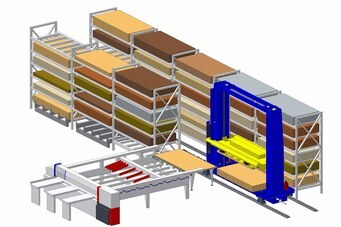

SYSTRAPLAN is known in the industry as a guarantee of solidity, reliability and commitment.The center piece of the VOLKSLAGER is a rack serve carrier developed for the lower price segment. At first glance, it is already clear that its design differs from the well-known conventional rack serve carriers.

Decades of experience in the construction of rack serve carriers have been incorporated into the development. The demand for quality, functionality and longevity remains with the VOLKSLAGER.

This video will be loaded from Google YouTube.

Their privacy policy applies.

Their privacy policy applies.

The VOLKSLAGER advantages

Direct access in the storage

The time and energy consuming re-stacking in order to get the required board variants, which is common in area storage with stacks up to 2m high, can be avoided.Especially interesting with a high number of variants

When the stack height in the rack is low, the rack serve carrier is used to access the board material directly.

In this way, a large number of different panel variants can be accessed without having to relocate panels.The workshop height is used

Even with a low hall height of 4m, the high-bay storage system does not need to be afraid of the comparison with an area storage system. With an assumed identical space utilization of 200 m² (e.g. approx. 30x7m), a storage capacity of up to approx. 80 stack locations can be expected.

A comparable area storage system has a storage capacity of up to approx. 25 stacking places. The advantage of the high-bay storage grows with increasing building height and in this way the growing number of variants, which is becoming more and more important nowadays, can be taken into account.Individual, customer-specific design

With the numerous options offered, the system is expandable and can be designed individually according to the performance and space conditions of the customer.

High performance

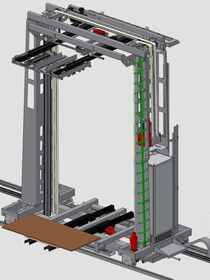

Compared to a large-area storage system, the VOLKSLAGER ensures a higher performance due to direct access to many different panel variants on the shelf.Picking directly on the rack serve carrier

The order picking of single panels can be realised at our VOLKSLAGER directly on the storage and retrieval machine.

The order picking of single panels can be realised at our VOLKSLAGER directly on the storage and retrieval machine.

For this purpose a stack platform is integrated in the base frame, which can optionally be equipped with stack telescopes or a chain conveyor. An additional area, in which order picking often takes place downstream, is no longer necessary and thus provides additional cost savings.Damage-free handling

One of the most important advantages is the damage-free handling of the wood based or panel materials. The panels, whose surfaces are often very sensitive, are properly prepared for processing in a very short time. The automatic storage and retrieval systems works continuously and damage to edges or surfaces is eliminated by the automation.

One of the most important advantages is the damage-free handling of the wood based or panel materials. The panels, whose surfaces are often very sensitive, are properly prepared for processing in a very short time. The automatic storage and retrieval systems works continuously and damage to edges or surfaces is eliminated by the automation.

Options for the VOLKSLAGER

Stacking telescopes in the base frame

The rack serve carrier takes the boards one by one with the suction frame to store or retrieve them. With optional stack telescopes in the base frame of the storage and retrieval machine, complete stacks can be moved in the lower level. With the integrated stack transport, the performance of the system can be increased even further by simple means. Fast moving stacks are stored as stacks in the lower level of the rack, commission stacks can be buffered in the lower level of the rack so that the storage system can work through without supervision.

The rack serve carrier takes the boards one by one with the suction frame to store or retrieve them. With optional stack telescopes in the base frame of the storage and retrieval machine, complete stacks can be moved in the lower level. With the integrated stack transport, the performance of the system can be increased even further by simple means. Fast moving stacks are stored as stacks in the lower level of the rack, commission stacks can be buffered in the lower level of the rack so that the storage system can work through without supervision. Direct connection to a panel saw

With the help of a flat vacuum suction frame, which can be moved out to both sides via telescopes, individual panels are safely separated from the stack on the shelf and fed directly to a panel saw.

With the help of a flat vacuum suction frame, which can be moved out to both sides via telescopes, individual panels are safely separated from the stack on the shelf and fed directly to a panel saw.

A direct connection of the VOLKSLAGER to panel saws is standard and has proven to be very advantageous at this point. Panel saws of different manufacturers have already been integrated in numerous projects.Several in and outfeed locations

In and outfeed locations with chain conveyor

In order not to have to stop the system during the in and outfeeding procedure, there is the option to equip the in and outfeeding places with chain conveyors and a safety barrier. This way the operator can place the stack and feed it through the safety channel to the storage system without having to stop the VOLKSLAGER.

In order not to have to stop the system during the in and outfeeding procedure, there is the option to equip the in and outfeeding places with chain conveyors and a safety barrier. This way the operator can place the stack and feed it through the safety channel to the storage system without having to stop the VOLKSLAGER. Double panel detection on the suction frame

PC warehouse management

The warehouse management is carried out with a specially developed software based on PLC and is operated via the Siemens control panel. The Siemens control panel, with a large display, has the possibility to connect a keyboard and mouse. This ensures a user-friendly handling.

The warehouse management is carried out with a specially developed software based on PLC and is operated via the Siemens control panel. The Siemens control panel, with a large display, has the possibility to connect a keyboard and mouse. This ensures a user-friendly handling.

As an option, we also offer a PC warehouse management system with which a connection to the higher-level control systems can be realized. Here we work together with long-standing partners who are specialized in individual software solutions.

Logo Erwin Krüger KG

In Berlin they place great emphasis

on scratch-free coatings

Additional interesting information

Shelf system

Steel racking construction consisting of double rows of shelves for single-deep storage of stacks on supporting beams made of box sections. The steel racking structure is provided with all necessary horizontal and vertical bracing.

Steel racking construction consisting of double rows of shelves for single-deep storage of stacks on supporting beams made of box sections. The steel racking structure is provided with all necessary horizontal and vertical bracing.

Pushthrough protection for rows of racks that are not against a wall, depth supports for storing strip material, hat profiles for storing stacks at the lower shelf level are optional.Fire protection & sprinkler system

The fire protection equipment must be designed in accordance with local regulations and coordinated with the local authorities. The regulations vary greatly from site to site, so that there is no typical fire protection.

In some cases insurance companies prescribe a certain level of fire protection, otherwise the rates will increase dramatically. This must be agreed individually with your insurance company.

If a sprinkler system is required on the shelf, it must be decided how many shelf levels must be sprinkled with how many sprinkler heads. Then the piping and the position of the sprinkler heads must be determined. The pipes and the heads must be in the shadow of the shelf frames, otherwise additional space and in the shelf compartment would be required.Foundation requirements for the Volkslager

- Load max. 50 - 100 N/cm2 alternating,

- Anchorage with expansion anchor or chemical anchor studs,

- Drill hole depth max. 180 mm,

- The load capacity of the floor must be in accordance with the required load,

- Grouting of the foundation plates after installation with shrink free casting compound will be provided by the customer,

- The floor tolerance must be in accordance with DIN18202, sheet 3, line 3 (on the complete length not more than 15 mm)

This information are without any obligations and only reference values. The stated values, especially the exact load capacity, can only be defined after clarification of all details during the design period.Installation site / earthquake zone:

Please check and inform us about the earthquake zone to be considered. The earthquake zone is important for the design of the shelf structure, which has a significant influence on the price. The customer is obliged to inform Systraplan about the earthquake zone as well as the ground class of the later installation site. If we do not receive any information, no earthquake zone will be taken as a basis for the price calculation.

Details about energy recovery

An increasingly important argument in favour of purchasing a system from Systraplan. Industrial electricity prices have rocketed over the past few years. According to the calculations of the Essen branch of the German Association of Industrial Energy Consumers (VIK), industrial electricity prices have virtually gone through the roof, with an increase of 35%. Systraplan tackled this subject at a very early stage and has been relying on the proven energy recovery technology for years.

Details about warehouse management

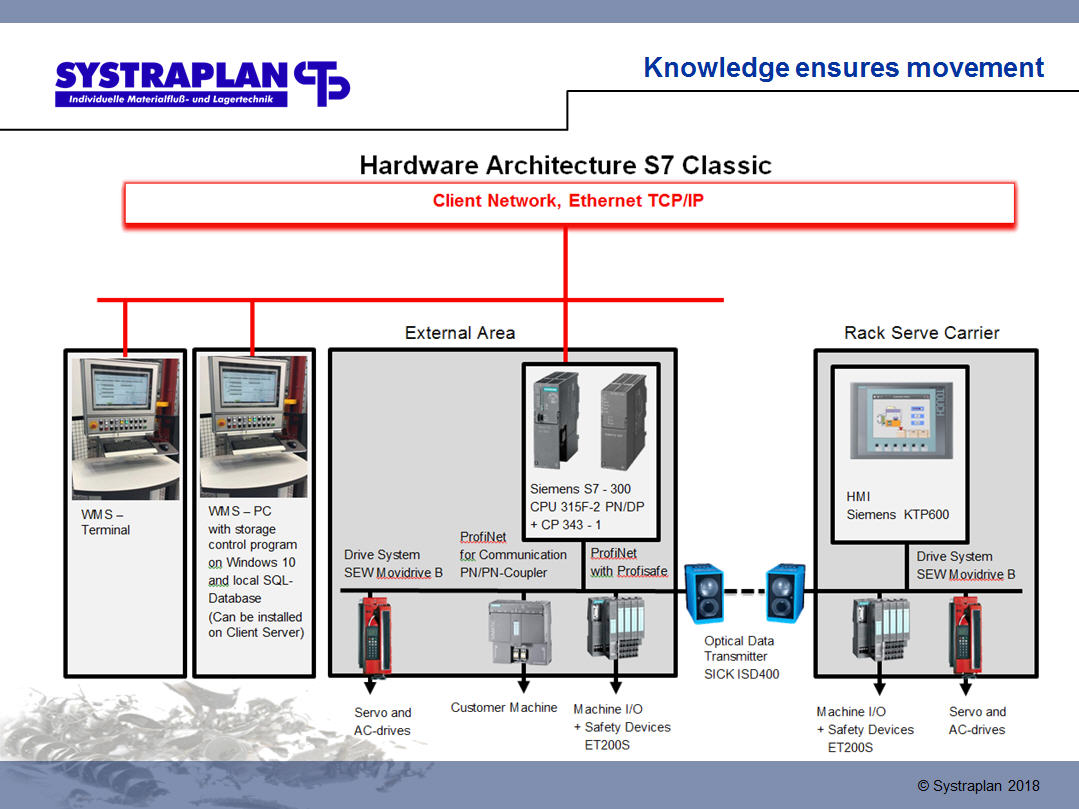

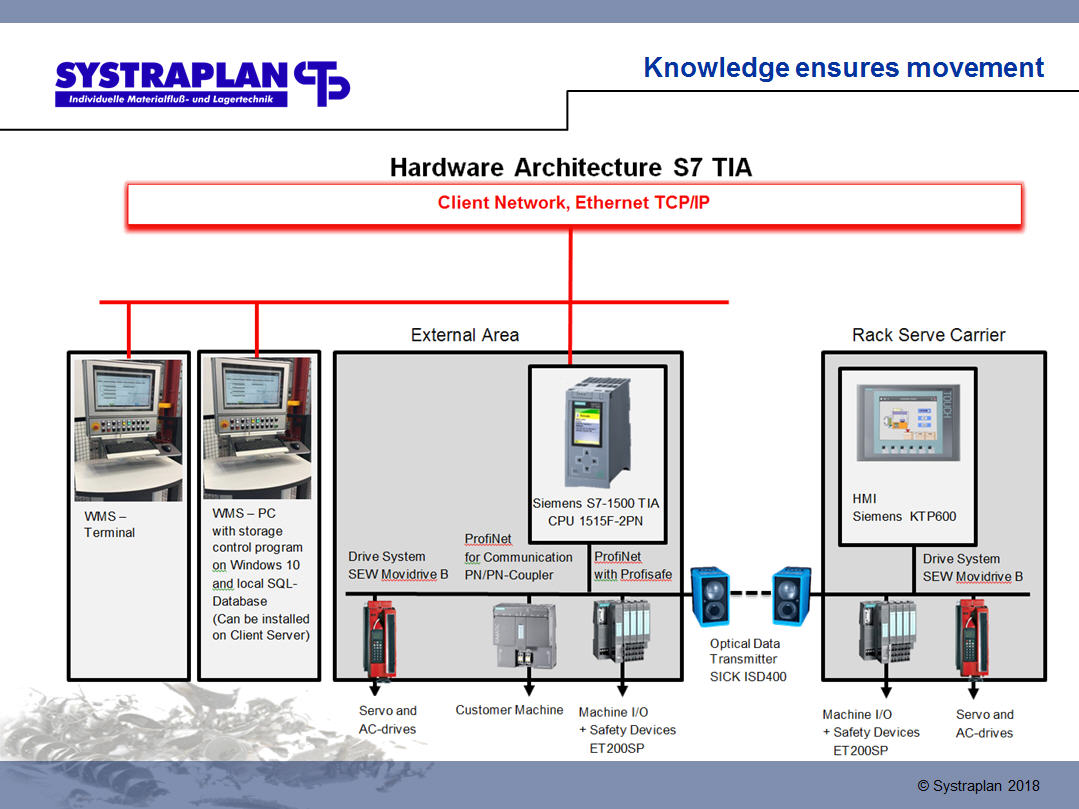

SYSTRAPLANs’ storage and control program can be operated under the Microsoft operating system Windows. This guarantees that today’s and tomorrows requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.

SPS Concept SIEMENS S7 Classic

SPS Concept SIEMENS S7 TIA

The VOLKSLAGER

We are developing solutions today for your future needs

Let us know your individual requirements.

We will work out a concept tailored to your needs

We will work out a concept tailored to your needs