20.September 2016

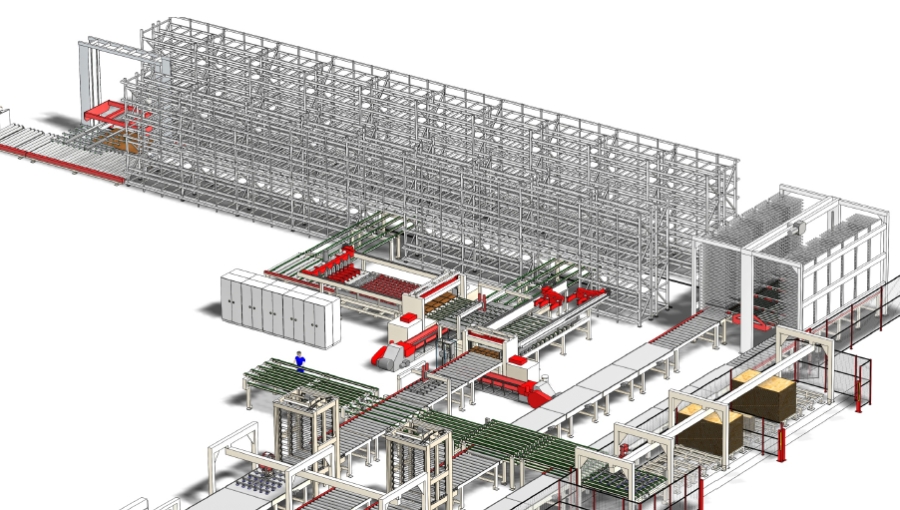

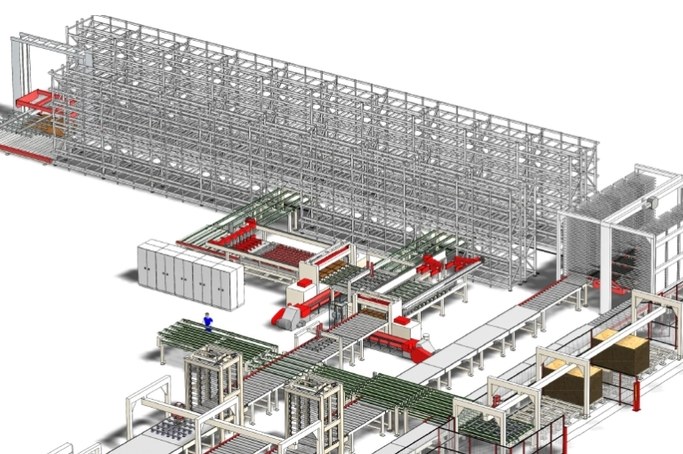

VOLKSLAGER – High Bay Storage System and Compact Sorting Warehouse – Efficiency Enhancement by Material Flow Optimisation

KINNARPS AB in Schweden is one of the largest producer of office furniture in Europe. The order for the overall project was awarded to the ANTHON GmbH in Flensburg and will be implemented in cooperation with IMA, PRIESS & HORSTMAN, 3Tec and SYSTRAPLAN.

Material Flow Optimisation:

To get a grip on the material flow of the batch size-1-production is surely a challenge. This can be achieved by simple and manageable investments in the right place. So the provision of the panel material is already automated by means of a high bay storage system. The SYSTRAPLAN warehouse system allows the storage and retrieval of stacks in the lower level as well as to separate single panels. The crosscut saw is directly connected to the warehouse system. Larger residue plates will be returned and restored.VOLKSLAGER: Direct Access to a Large Number of Panel Varieties

With a simple but efficient high bay storage system and low stack heights in the rack the system ensures a high performance by a faster and direct access to a great number of various panel types. Time and engergy consuming restacking in order to reach the needed panels, as it is usual with stacks of 2 m height in area storage system, can be eliminated.Compact Sorting Warehouse: Buffering and Sorting of Work Pieces

Work pieces are intermediately buffered between the individual processing steps by means of a compact sorter and are then made available “just-in-time” in a new optimized sequence for the succesive processing step. This is accomplished in this case between edge processing and drilling.This not only allows to optimise the manufacturing process when manufacturing furniture components, but also opens new possibilities that lead to an efficient production.

Targets of a Sorting System:

- Optimisation of the active processing speed

- Optimisation of the changeover times

- Smoothing of production utilisation

- A more uniform production based on the premise „batch size 1“

- Allowing several orders for the next dispatch date as well as following orders with identical machining – so-called „can-parts“ – coming with a later allocation from the sorting warehouse

- To gain same production time für A-, B- and C-quality goods

- To supply the processing machines just-in-time

- Best possible utilisation of the resources

Minimising waste

All these tasks can be processed or optimised in a single or combined way by the compact sorting warehouse.

Manufacturing Control System

The administration of stockpiles, the control of all operations as well as the optimisation of individual stipulated criteria are based on a 3Tec manufactruing control system. The customers’ individual requests are decisive for the design and planning.In fact, in implementing the establishement of the size-1-production these systems become more and more important for the material flow optimisation in production.