13.October 2016

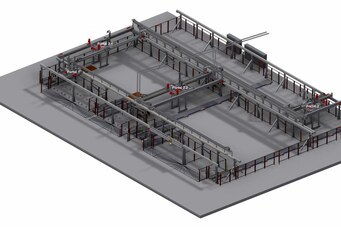

New Area Storage System with Stack Transportation

The Westag & Getalit AG successfully operates with similar area storage systems based on the same design for many years now. For the customer it was important to fall back on SYSTRAPLAN’s proven technology.

Combined Lift Cage for Stacks

The customer has now chosen an area storage system of the latest generation with a combined lift cage for stacks. This lift cage is capable to lift and single stacks up to a length of 3,100 mm.

The customer has now chosen an area storage system of the latest generation with a combined lift cage for stacks. This lift cage is capable to lift and single stacks up to a length of 3,100 mm. These area storage systems enable to convey stacks and single boards. The space needed in the hoisting system is created by raising the clamp frame by means of a separate lift. For conveying single boards the clamp system is activated by lowering the separate lift.

Safe Stack Transportation – No Board Shifting

For the storage and the retrieval of boards the lift cage is put over the stack. Then transport fingers swivel under the stack and take up the weight of the stack.Underneath the stacks are either pallets or carrier plates positioned on bed lumbers.

Furthermore, the hoisting system is equipped with a suction cup unit for soft fiber strips in order to place these between certain materials. It will be activated on demand.

The systems‘ clamp frame serves to fix the stack by means of its weight whilst conveying the stack, and thus avoids a possible shifting of the doors.

Individual Design Decides Warehouse Performance

Individual requirements are decisive factors for the warehouse construction. Depending on system, dimensions and design, the warehouses’ performance averages to approximately 25 seconds in single board cycle.

Individual requirements are decisive factors for the warehouse construction. Depending on system, dimensions and design, the warehouses’ performance averages to approximately 25 seconds in single board cycle.Removal with Direct Connection to Dispatch Department

The retrieval of doors picked is performed on centrally placed conveyors which provide the relevant space to build buffers and to supply the doors directly to the shipping stations. Alternatively, consigned stacks can be build at a central position for subsequent further processing.Waiting Times at Downstream Machines Omit

An automated system operation of the warehouse reduces not only the current personnel expenses, the quick access of the area storage system also avoids waiting times and thus creates a continuous workflow.

An automated system operation of the warehouse reduces not only the current personnel expenses, the quick access of the area storage system also avoids waiting times and thus creates a continuous workflow. The system places the boards into storage whilst the buffer that was built is being processed by downstream systems.

Fast Access, Automatic Operation

A fast access is guranteed, because the system knows exactly where what is stored and the shortest way for storing and retrieving goods at any time.The system operates whilst the next job is entered or transferred. In the event of waiting times goods can be pre-picked or placed into storage. An appropriate software for these processes was especially created at the customer.

Material is Carefully Handled

One of the most important advantages is the damage-free handling of the doors. Whilst processing the doors the area system operates continuously at a comparatively high speed.

One of the most important advantages is the damage-free handling of the doors. Whilst processing the doors the area system operates continuously at a comparatively high speed. Most suitable for feeding production machines, for intermediate buffers in the production or as exclusive storage system.

Storage and Control System

SYSTRAPLAN’s storage and control program can be operated on standard PC systems under the Microsoft operating system Windows.This guarantees that today’s and tomorrow’s requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software.