AUTOMATIC FEEDING OF PANEL SAWS

Panel sizing service with the aid of an automatic warehousing and feeding system from SYSTRAPLAN

HORATEC in East-Westphalian Hövelhof sees itself as a service provider for the woodworking trade and supplies carpenters and cabinetmakers with customized furniture parts from a batch size of one.Two panel sizing saws have been combined with a high bay panel storage facility and an automatic gantry feeding system via a master computer and effective software to form a highly efficient and intelligent manufacturing unit. A concept that is proving highly successful.

Reported from the practice:

Organized and efficient manufacturing process and perfect quality

“As a supplier of the discerning cabinetmaker’s trade, we must be able to rely on an organized and efficient manufacturing process while ensuring perfect quality, “Wolfgang Thorwesten, the Managing Director of HORATEC, explains.

Two panel sizing saws are part of the manufacturing concept realized by HORATEC in Vlotho with the cooperation SYSTRAPLAN in Herford and 3TEC. Two panel sizing machine lines are located directly at the storage facility from where they are fed by forklift truck via four slide-in compartments.-

Drawers, which are accessed alternately with the line gantry

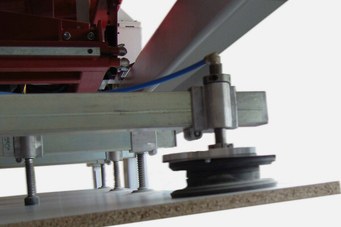

[image_l=410#0,410]We decided in favor of a high-bay storage facility with slide-in compartments as this allows optimal utilization of the existing space, direct access to the panel material and minimizes the material handling time,“ Thorwesten explains.

Each of the saws is equipped with two slide-in compartments that can be loaded alternately by the loading device. While material from one compartment is being fed to the first saw by a large-area vacuum gripper, the second compartment can already be loaded again. “In this way, we can ensure that the saws are permanently in operation and virtually eliminate the previously non-productive material handling times. This handling solution alone has resulted in a 30% increase in productivity," Thorwesten reports. -

Effective software from 3TEC

The entire process is controlled with the aid of effective from 3TEC via a master computer. The orders entered into the system are continuously processed and the cutting patterns automatically generated so the user only has to attend to the finished cut-to-size panels.

The fact that the new saw is used together with industrial control systems such as Siemens S7, standard PCs with Windows as well as Profibus systems offers a huge advantage, as the control and software connection, in particular, is important for connecting a feeding system.

Intelligent off-cut management

[image_l=414#0,414]Another important aspect of the manufacturing concept is the intelligent management of off-cuts. “All off-cuts produced when the material is cut to size are automatically transported to the off-cut storage and managed by the master computer," Thorwesten explains. This means that when the residual panel is transferred, the respective information regarding the off-cut, such as material and decor type, grain direction of the decor, dimensions and position of the off-cut are transmitted to the higher ranking control system. The respective off-cut can be quickly returned to the manufacturing process if required. “In this way, we effectively manage the off-cuts and maximize material utilization,"Thorwesten explains enthusiastically.-

Combines the advantages of an area and a cantilever rack storage system

This solution essentially combines the advantages of an area and a cantilever rack storage system that comes into its own with the “intelligent“ connection via the master computer to the automatic feeding system and panel sizing technology to increase productivity. “This system considerably reduces non-productive times, optimizes material utilization and ensures gentle handling of the panels,"Thorwesten explains, “this is particularly important for panels with increasingly more delicate surfaces."

Horizontal storage

We are developing solutions today for your future needs

Let us know your individual requirements.

We will work out a concept tailored to your needs

We will work out a concept tailored to your needs

A technical design which makes the difference

Fast order processing highest possible availability

Derived products are handled damage-free

One of the most important advantages is the damage-free handling of the derived products. Within short time the sensitive boards are appropriately prepared for the resale.

By doing so the automatic storage system operates continuously at a comparatively high speed.

It just takes a quarter of an hour to build a consignment of 15 different boards.

Direct connection to PPS - System

The electronic data processing control ensures fastest feeding and discharging, which facilitates the batch-, package- and piece-wise distribution.

All goods movement data are adjusted just in time by a direct linking of the full automatic storage system with the merchandise management system. Hence, the sales team can always revert to an up-dated asset of boards provided by an easy and interference-proof operating mode.-

Stock-status always available

SYSTRAPLANS’ storage and control program can be operated under the Microsoft Windows operating system. This guarantees that today’s and tomorrow’s requirements will be met also in future in respect of system design, flexibility and links to standard systems and standard software. -

State of the art graphical screen interface

References